The benefits of digital engineering

Enabling high-performance production sites with digital asset and supply chain engineering

Every production site has the potential to improve; to increase yield, boost efficiency and become more profitable. With digital asset and supply chain engineering, organisations can decommoditise their products and build high-performance production processes – but it requires the right approach.

Through established and emerging technologies such as parametric design, the Internet of Things (IoT), artificial intelligence, and digital twins, leaders can build robust ecosystems that make the most of resilient supply chains and intelligent assets. In this blog, we’ll discuss some of those technologies.

Through established and emerging technologies such as parametric design, the Internet of Things (IoT), artificial intelligence, and digital twins, leaders can build robust ecosystems that make the most of resilient supply chains and intelligent assets. In this blog, we’ll discuss some of those technologies.

Key take-aways

2. Intelligent technologies can revolutionise assets and supply chains

3. Organisations can overcome implementation barriers with an experienced partner

The technologies

1. Parametric design

This approach is the perfect way to generate efficient, effective design quickly – and adjust it when your plans need to change. Parametric design uses relational building information models, informed by parameters you set, to produce the optimum design.You can use this approach for everything from how you manage storage when raw materials come in from your external supply chain, to the best setup for your production line.

Last-minute changes no longer require weeks of redesign. You can simply input new parameters, and the model will update automatically. And because it automates the repetitive aspects of design work, your engineers can focus on the more complex areas of a project, where their expertise can make a real difference.

Parametric design is just one way to ensure your organisation is taking the optimum approach to operations – and it’s often supported by other data-led techniques.

2. IOT and AI

By drawing data in from IoT-enabled assets through sensors, cameras and internal monitoring devices, you can feed sophisticated AI models for rapid, intelligent analysis.For example, real-time condition monitoring can help you make accurate correlations between how a production site is set up, how individual assets are being used, and how that affects its lifecycle.

All this data can feed into your parametric models – or support digital twins and other simulations – to help you find the best approach to engineering your asset management and supply chain processes.

3. Digital twins and process simulation

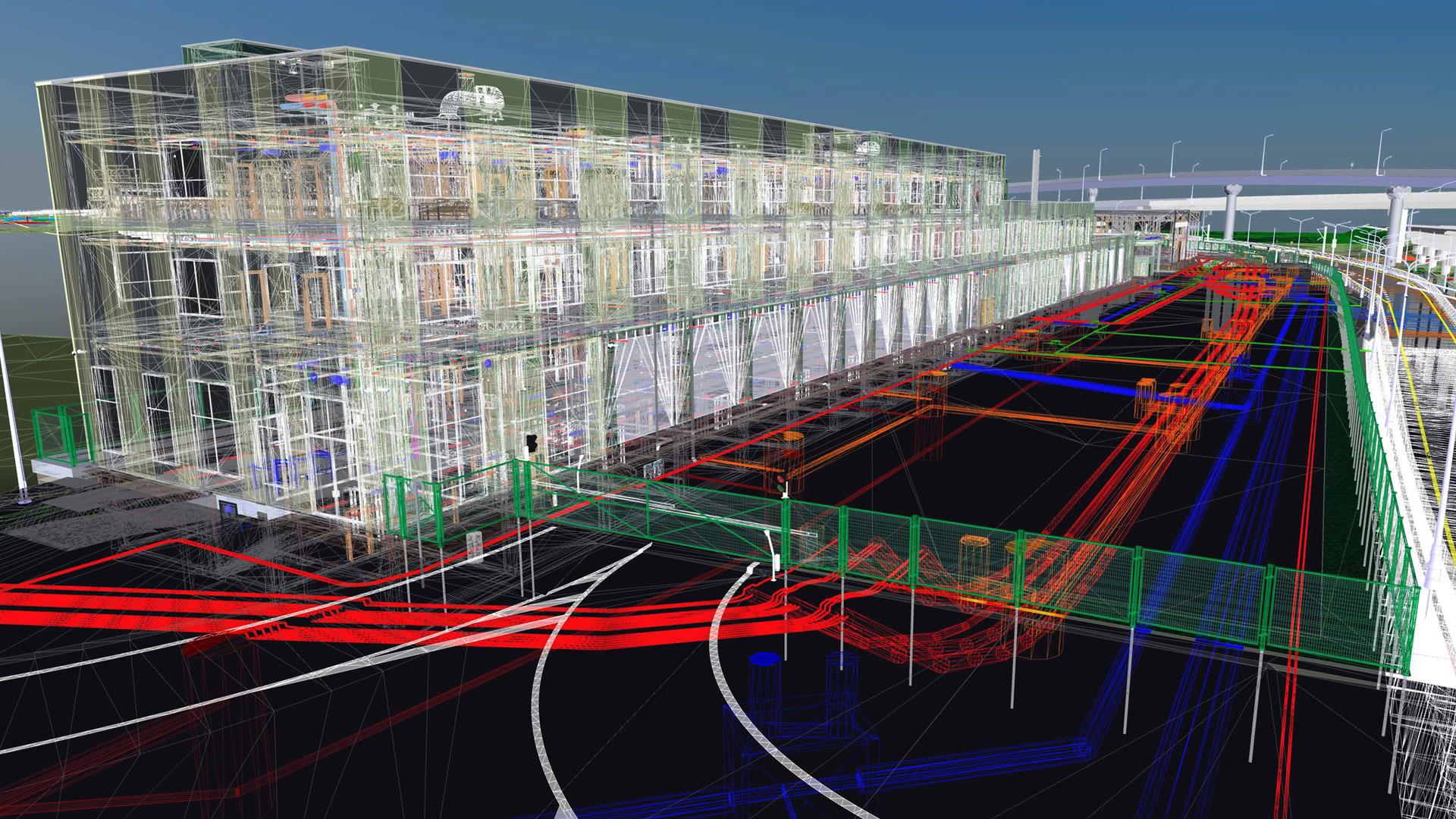

Simulation is a powerful tool that gives you predictive insight you can’t achieve any other way.A digital twin is a virtual representation of physical assets and their behaviours, using data from business systems, the environment, and the assets themselves. Process simulation gives you a similar opportunity to represent key business and supply chain processes digitally.

These approaches offer risk-free experimentation, as you can make changes virtually based on different sets of parameters without affecting your real-world production site or supply chain. For example, you can test the effect of increasing production rates or changing the supplier of a component on productivity, efficiency or profitability.

4. Blockchain

Using blockchain, a distributed ledger technology, organisations and their partners can stay connected and trusted. It’s perfect for supply chain engineering, as it bakes transparency into the process, end to end.Every agreement, process, task and payment has a digital signature that can be identified, validated, stored and shared. Transparency and trust at every step in the process helps eliminate risk, improve security and remove the need for intermediaries.

Each party in the ecosystem can see the status of their partners and shipments in detail, which also helps improve communication and collaboration across the supply chain.

Overcoming barriers to adoption

All of these technologies are ideal for communicating value to stakeholders and creating a continuous improvement loop for digital asset and supply chain engineering. But to get those benefits, you need to deploy them first.As with any emerging technology, there can be barriers that get in the way of implementation. Though organisations might have a clear goal for their assets and supply chains, it can be difficult to know where to begin.

To make digital asset and supply chain engineering a success, organisations need to have a deep understanding not only of their own operations, but of the data science that underpins this new approach.

Balancing the data, technology and engineering requirements can sometimes be tricky – and that’s where bringing in an experienced partner can make all the difference.

An expert in digital engineering

As experts in digital engineering, Royal HaskoningDHV Digital can help you make the most of these technologies, overcoming the challenges to establish resilient supply chains and boost asset performance.Combining our digital consulting services and software solutions with decades of engineering expertise, we’ll help you create an innovative industrial site that’s ready for the future.

White paper

Download our white paper

For a more in-depth look at the role digital twins have to play in the rise of Industry 4.0, read our white paper Demystifying Digital Twins.

Stayupdated

Keeping up to date with the latest digital twin news? We've got you covered