Liquefied Natural Gas Terminals

Current and future operators must balance environmental conditions, commercial, technical and operational risks, as well as costs in a dynamic market to ensure their terminal is successful.

Confidence

Trusted by over 100 LNG terminal developers

Clarity

High value design delivering solutions that work

Quality

Global technical expertise underpinned by cutting edge technology

Global leading maritime LNG terminal consultants

LNG terminals are often located in challenging sites, with multiple stakeholders and require expansive landside and port infrastructure. This means projects are complex and subject to numerous requirements from safety and environment to cost, operations, schedules, and quality assurance. So, it’s crucial to get it right.That’s where we come in. As global leaders in the design and optimisation of maritime facilities, we provide high-value designs, that work within the environmental constraints and physical environment ensuring low risk, high reliability, and longevity over the project life cycle.

During the earliest stages of planning LNG facilities, we work collaboratively with you to identify your operational performance objectives. Through engineering and scientific rigour, we help assess the physical environment, from waves and currents to ground conditions and all other relevant site characteristics.

We use this information to build concepts that work for the natural conditions of the site location, the vessels that use the facility and the operational performance objectives. We provide a comprehensive design service to create new infrastructure for you or upgrade your existing assets.

This includes the design of navigation channels to allow safe access, and breakwaters that improve operability at the berth, plus efficient dredging plans for construction and operations, as well as mooring arrangement design and technology.

LNG maritime consultants – small scale LNG

The market for small-scale LNG is growing rapidly. LNG is being used more frequently to fuel ships. The need to transport LNG in smaller cargo ships and to smaller facilities is increasing, too.

With the right infrastructure and processes in place, LNG containers can be shipped on normal container ships. So, our container terminal expertise is valuable in developing facilities within which operations meet the specific requirements for the handling of dangerous cargoes, specifically LNG.

As LNG maritime consultants, we can help you assess possibilities for the whole LNG transport and value chain, from large to small-scale LNG projects. Where LNG bunkering and its facilities are involved, you can also make use of our connections within the Society for Gas and Marine Fuel (SGMF).

Setting the standards

We have participated in many national and global technical committees including the PIANC Maritime Navigation Commission Working Group WG153B report: “Recommendations for the design and assessment of marine and petrochemical terminals,” specifically updated for LNG terminals. We are committed to the development and deployment of best practices for your benefit.

Our technical expertise is underpinned by our adoption of cutting-edge technology. You can benefit from our smart solutions like Building Information Modelling (BIM) and parametric design, liquid bulk terminal simulation (WITNESS), and a variety of other digital tools, to develop your terminal fully in line with the latest industry innovations

LNG terminal digital twin (Twinn) simulation

Over the past 20 years, we have developed an LNG Logistics Simulator which is used by us and our clients around the world.

"Simulation helps us figure out the major design issues that we couldn’t see on paper. And that means finding out what works – and what doesn’t from our terminal risk evaluations before we sink time and money into marketing and shipping opportunity assessments built on flawed thinking”

The Twinn LNG logistics simulator is a discrete event WITNESS based decision support application providing independent validation of technical assumptions, future operating rules and long-term commercial viability.

Simulation models across the value chain and throughout the project life cycle include:

- Pre – Front End Engineering Design (FEED) analysis studies

- FEED study and Basis of Design (BoD) validation

- Terminal Use and shipping studies

- Annual Demand Plan (ADP) calculation & testing

- Sales and Purchase Agreement (SPA) evaluation/ risk studies

- Terminal User agreement

- Shipping/Marketing portfolio studies

- Future expansion validation

Smart mooring

We create safer, smarter and more efficient ports with a predictive decision support solution that uses real-time data and metocean forecasts to enhance vessel mooring and related operations.

When it comes to mooring, each individual port, terminal, and individual berth has different safety and operational needs. LNG terminals specifically have high safety standards and our skills and tools can help to reduce operational risk. .

With Smart Mooring, you can create the perfect overview, with decision-making for every berth on the map supported by the right levels of intelligence.

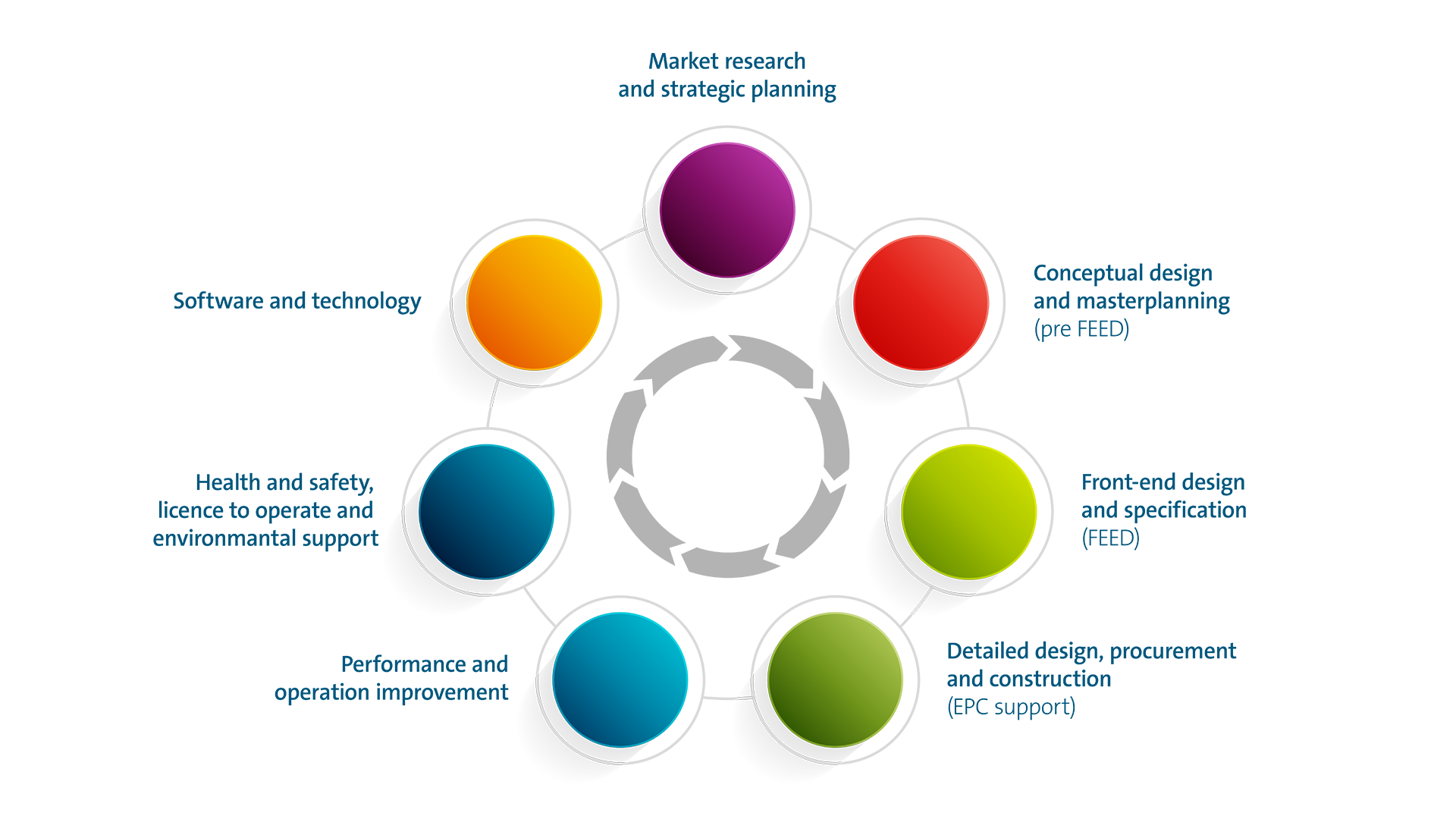

Our LNG terminal capabilities

We have intimate knowledge of marine operations and infrastructure – from the technical nuts and bolts up to the strategic business advice and decision support, so we can help make your LNG terminal work.

Our LNG export and LNG import terminal capabilities include:

- Site location studies

- Terminal development plans and feasibility studies

- LNG terminal planning

- Floating storage and regasification unit (FSRU) versus onshore terminal assessment

- Terminal traffic forecasting and logistics analysis LNG predictive supply chain logistics digital twins

- Bathymetric and geophysical survey support

- Shipping and navigation studies

- Geotechnical design & survey support,

- Engineering [pre-FEED and FEED studies]

- Outline design of product handling systems

- Mechanical and electrical services

- Fire-fighting design

- LNG jetty design

- Combined LPG-LNG jetties planning

- Metocean and hydrodynamic modelling

- Dynamic mooring analysis

- Foundation engineering

- Mooring design

- Design of breakwaters and coastal structures

- Design of cooling and heating water intakes and outfalls

- Sedimentation assessment and dredging design

- Bid documents development, technical query support, bid appraisal and review

- 3rd Party independent review (Cold eye review)

- Environmental and social impact assessment

Maritime challenges

To create future-proof maritime facilities that will continue to thrive for decades to come, you need a combined digital, sustainable, and climate resilient strategy.

Learn more about what we can do for you:

- Digital transformation in ports, terminals, and shipyards

- Leading sustainability in ports, terminals, and shipyards

- Maritime climate adaptation and resilience

Our offerings

The drive to improve performance, energy efficiency, environmental standards and safety are ever present. Constraints over costs and timings add to the challenge. Find out how we can support with the challenges you are facing.

Discover why we’re the first port of call for:

Sectors we support

We are global maritime consultants specialised in the planning and design of marine facilities, ports and terminals, and shipyards.

Find out more about the sectors where we deliver our expertise: