Ephyra®

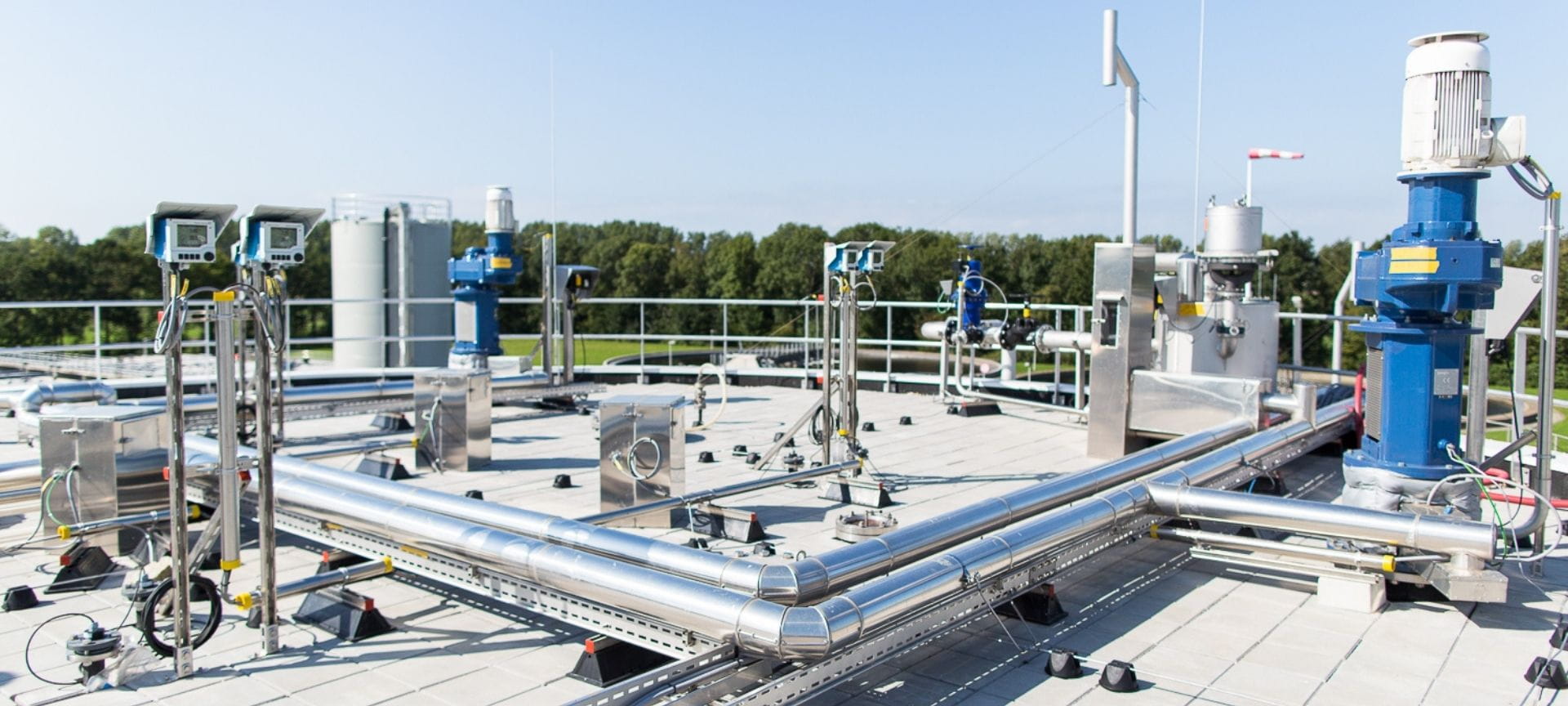

A compact and sustainable technology for sludge digestion, Ephyra is based on plug flow digestion, where the hydraulic retention time (HRT) and solids retention time (SRT) are separated. Reactor design, process control and operations have been optimised to improve performance and increase capacity. Ephyra is suitable for optimising both existing and new sludge digestion installations.

Now proven at full-scale for new and upgrade projects, Ephyra was originally developed by Royal HaskoningDHV in cooperation with STOWA (Foundation for Applied Water Research), Waterboard Zuiderzeeland. (The project was co-financed with a contribution from the LIFE financial instrument of the European Union and with the Top Sector Energy subsidy from the Ministry of Economic Affairs.)

In comparison to a conventional sludge digestion installation, Ephyra provides:

More sustainable energy in terms of increased biogas production

Less residual sludge

Much shorter payback time of only two to five years

Reliable operation at lower retention times to increase throughput by up to 50%

Shorter hydraulic retention time, resulting in smaller tank volume or increased capacity of existing tanks

The process

Ephyra operates three or four digesters in series to achieve high-rate plug-flow anaerobic digestion. Controlled recirculation optimizes the conditions in each digester. A unique feature of Ephyra is that it enables digestion at a very short sludge retention time of just six to eight days. These short retention times result in increased reactor capacity and a reduced footprint for new build digesters. The system is operated by an advanced software platform, the Aqua Suite Ephrya Controller, which ensures stable operation of the Ephyra digesters and includes adjustable recirculation for optimum process performance.The benefits

In comparison to a WWTP with a traditional sludge digestion installation, Ephyra operates at significantly lower retention times to increase throughput by up to 50%. As well as being suitable for optimizing new advanced digestion installations, the technology can be easily retrofitted, providing a no-build solution through reconfiguration for optimum performance. It can improve the performance of existing digesters and increase their capacity by 50-80%. Ephyra also uses less energy, and fewer chemicals while producing more biogas, making it a highly sustainable process. It also allows for the use of modern heating alternatives, such as heat pumps.Operational benefits

- Expansion of sludge processing capacity by 50-80% without increasing reactor volume

- Enhanced (20% to 30%) biogas production, due to a higher breakdown of sludge

- Up to 20% improvement of the total energy consumption of the WWTP

- Smaller reactors required, due to a higher sludge concentration

- Compact construction

- Easy to retrofit and to operate

- Improved conventional anaerobic digestion

- Lower use of chemicals for sludge thickening

- Better dewaterability of the digested sludge

Want to know more or got a question?

Contact our BioResource experts!