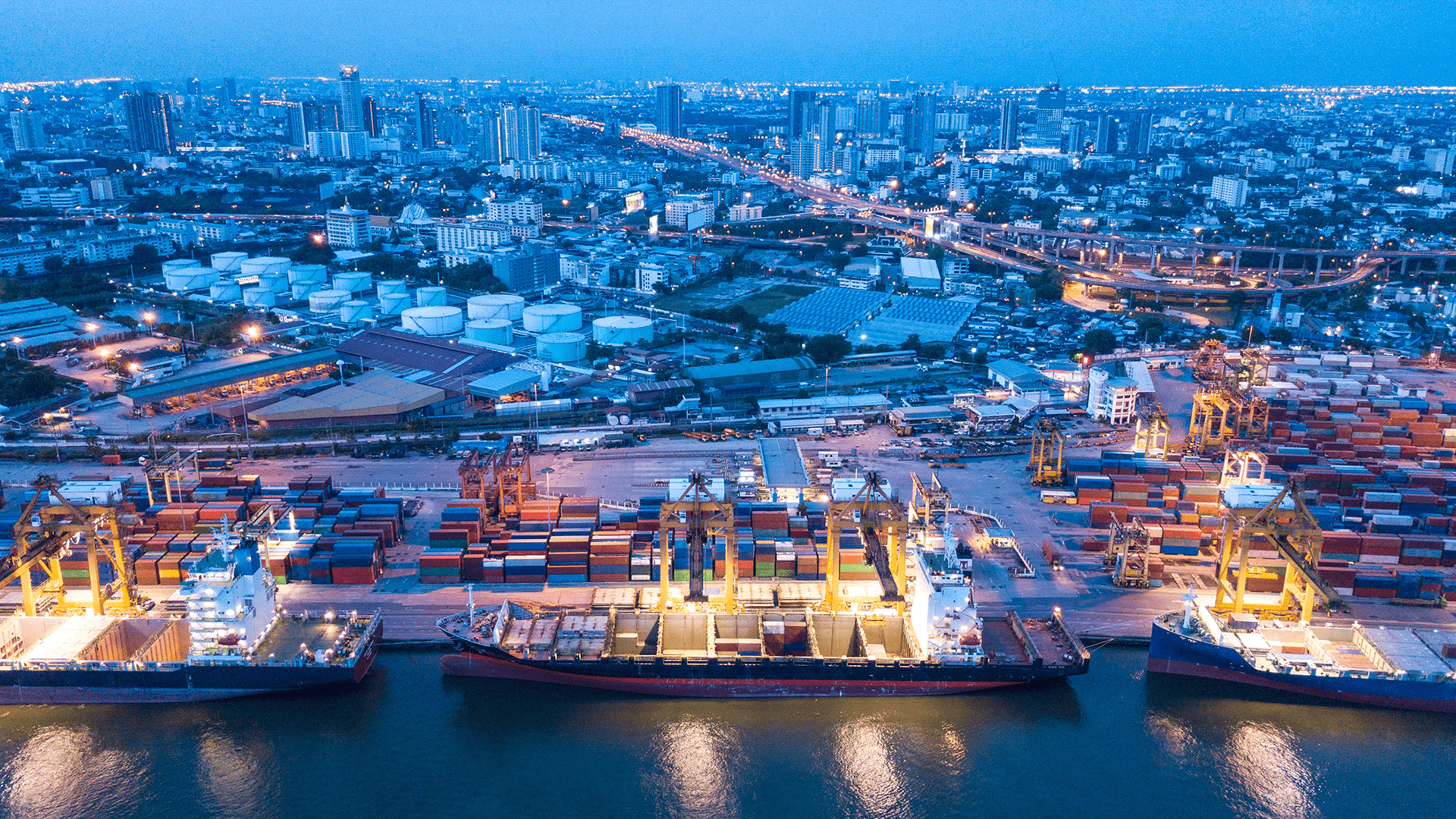

Maritime assets have long lifecycles and must operate effectively in harsh environments to keep your facility running smoothly. Your assets have to work together to make your facility safe, resilient, and efficient – but keeping track of their condition and maintenance can be complex.

You need to appropriately maintain a variety of assets, each with different usage, lifespans, service agreements, and performance demands. And to get the most return from these large-scale investments, you must keep them functional through market, environmental, and regulatory changes.

Asset management doesn’t, however, stop at maintenance. By optimising your most business-critical assets with digital technology, you can maximise their performance, and efficiency, while delivering even more value to staff and customers.

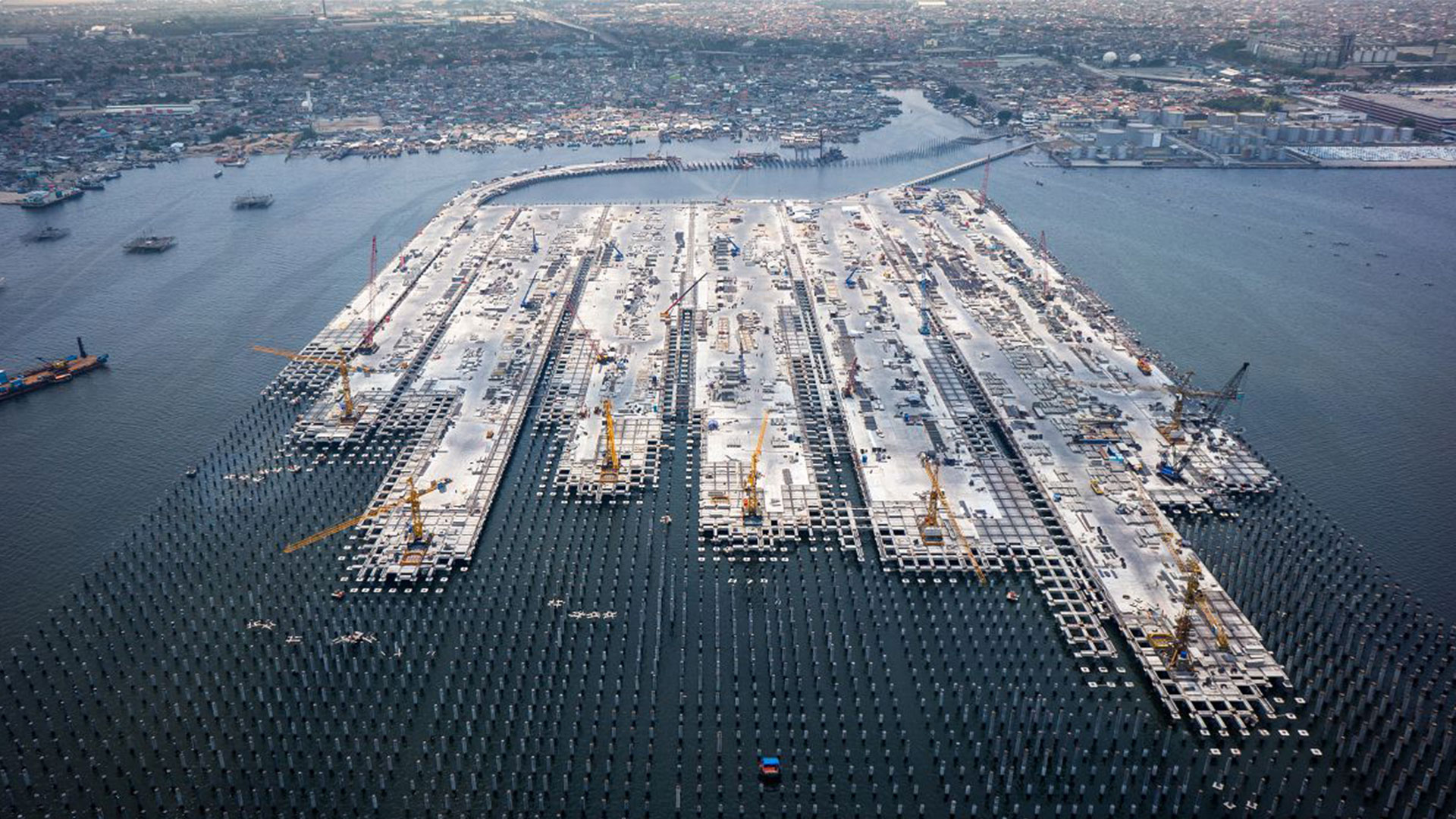

At Royal HaskoningDHV, we’re world-leaders in port and infrastructure design with over 140 years’ experience. We bring together digital tools and industry-leading expertise to provide a fresh approach to maritime asset management.

Guided by international best practice, our team will help you get the most out of your existing assets and the way you work with them. We can also support you with strategic guidance to make sure investments in new assets deliver maximum value and long-term resilience.

We’ll open the door to the latest technology innovations, too. From BIM and drones to AI and investment strategy, our team can support you with innovative asset management techniques that will help you create a port that’s ready for the future.